How data-based simulation helps to reduce costs and ensure service quality

The so-called last mile is the crucial stage in the supply chain – especially in food logistics. Between the kitchen, warehouse or distribution centre and the customer’s front door lies the part of the supply chain that determines speed, freshness and customer satisfaction. At the same time, this phase is often the most expensive and most difficult to plan part of the entire logistics process.

Increasing order volumes, high customer expectations regarding delivery times and a sensitive cold chain present companies with the challenge of balancing efficiency, sustainability and reliability. This is precisely where the simulation of delivery networks with tools such as AnyLogistix offers a decisive advantage.

The complexity of the last mile: time pressure and temperature sensitivity

There is hardly any other area where so many influencing factors come together as in the last mile of food logistics.

- Delivery times are often limited to a few hours.

- Vehicles must transport temperature-controlled goods.

- Customers expect flexibility in time windows and delivery options.

- Cities make route planning difficult with traffic density, environmental zones and parking restrictions.

Every small delay can result in high costs – whether through energy loss, increased return rates or loss of customer satisfaction.

Simulation as a decision-making tool

Traditional planning approaches quickly reach their limits in such dynamic environments. Simulation offers the possibility of realistically mapping complex delivery networks and optimising them based on real data.

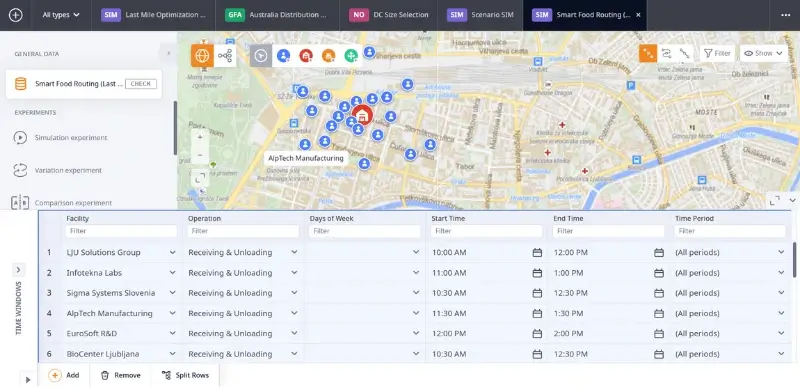

With AnyLogistix, for example, different scenarios can be compared:

- What are the effects of centralised versus decentralised warehouse structures?

- How do costs and service levels change when micro-hubs or urban depots are set up?

- Is it worth using electric vehicles or alternative delivery models?

- How does rising demand affect utilisation and punctuality?

By combining scenario analysis and dynamic simulation, cause-and-effect relationships become visible that remain hidden in static models. This enables companies to make data-based decisions about which measures will have the greatest impact in their specific environment.

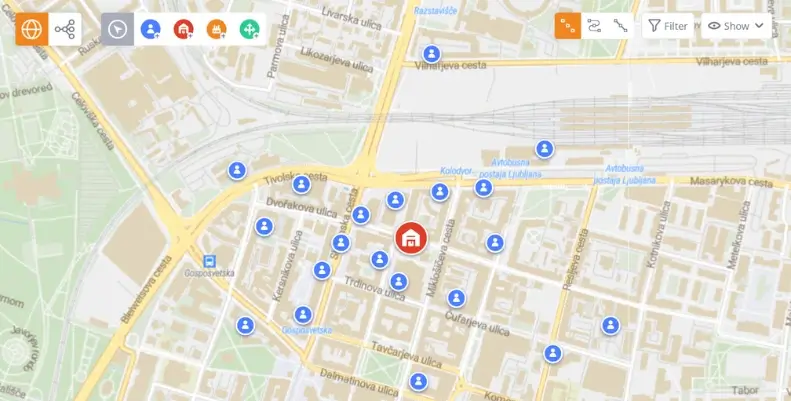

Practical example: Simulation of a food delivery supply chain

An example from the AnyLogistix blog clearly illustrates the potential:

A food delivery service used simulation to investigate how different network structures affect efficiency and customer satisfaction.

The company modelled three variants:

- Centralised delivery network with one main warehouse,

- Decentralised structure with several regional hubs,

- Hybrid model with central procurement and urban micro-depots.

The result: Through the targeted use of simulation, bottlenecks were identified, routes optimised and unproductive journeys reduced. The selected configuration resulted in:

- 20% lower delivery costs,

- more stable delivery times despite rising demand,

- and better fleet utilisation.

Such analyses provide a sound basis for decision-making – long before real investments are made in infrastructure, vehicles or personnel.