How to make supply chain projects a success with a clear structure

Structured project management in the supply chain: preparing decisions

Efficient decisions are a key success factor in supply chain projects – especially when complex dependencies, many participants and a high degree of uncertainty come together. This makes it all the more important to structure supply chain design projects clearly.

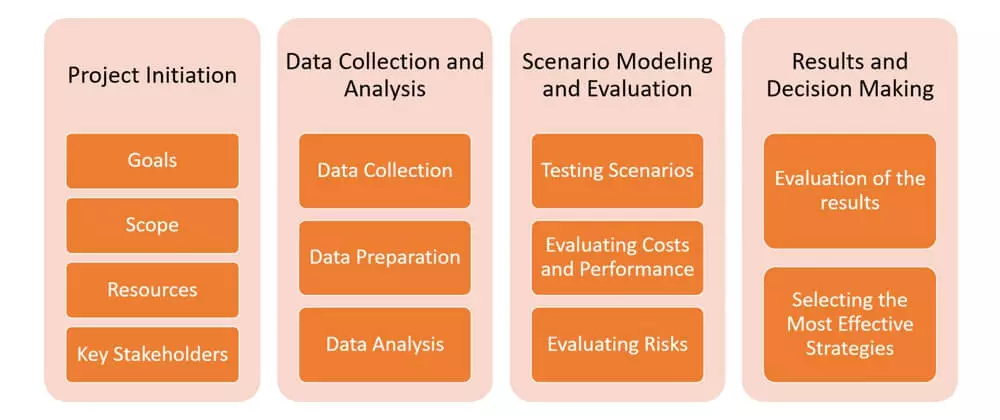

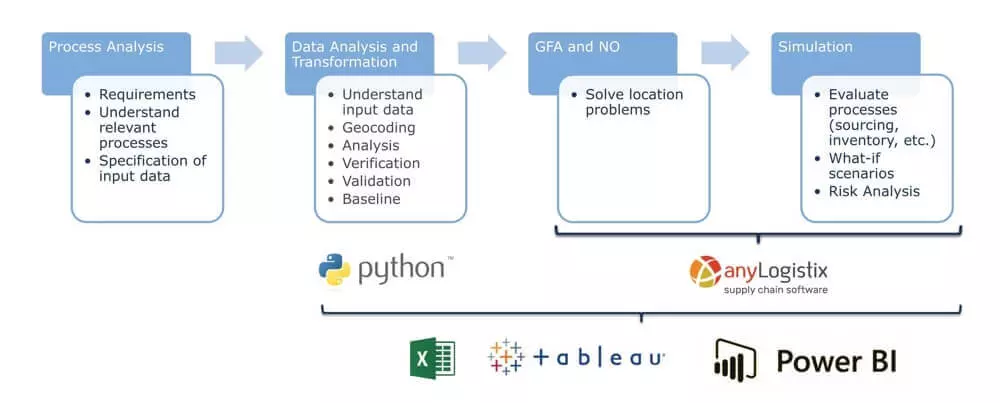

A structured project approach not only defines goals, but also facilitates data analysis, communication within the team and the selection of suitable methods – be it optimisation, simulation or a combination of both.

Why structure is crucial

A clear project structure…

- defines goals and success metrics,

- reduces complexity through comprehensible phases,

- promotes collaboration between departments,

- improves the quality and traceability of decisions.

This structure provides a clear framework – especially when simulation or optimisation tools such as anyLogistix are used.