Our series: Supply Chain Simulation / Part 10

Production capacity planning with supply chain design software tools

Your production plans must meet the requirements of your supply chain, such as demand, shipping conditions, downstream inventory policies and more. To meet these requirements, your production capacity planning software tools must provide functionality that allows you to find and evaluate appropriate solutions, as well as calculate the ROI of your network changes.

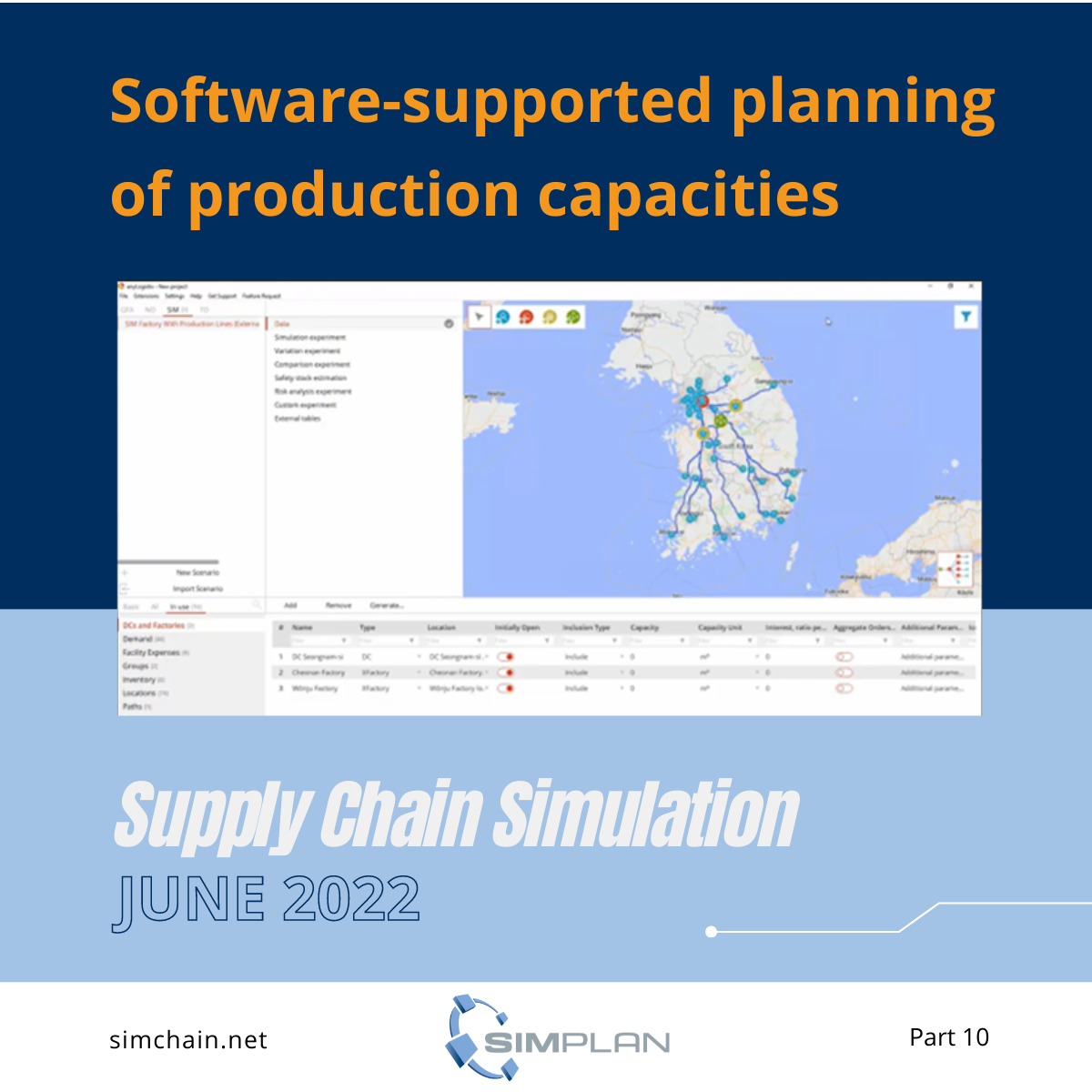

For example, use anyLogistix (ALX) for production planning to adapt the design and management of your supply chain and stay ahead in the ever-changing global economy.

Optimise the manufacturing footprint

With ALX, you can decide where to locate your manufacturing facilities, what goods to produce there and what their capacities are. Find the best strategies for your supply chain challenges, such as

– Relocating your production facilities to a low-cost country, taking into account transport times and service levels.

– Outsourcing production of some parts (offshoring or nearshoring) and selecting optimal supplier combinations.

– Matching capacity and demand across the entire bill of materials, taking into account fluctuations in demand.

Planning production capacity

Sometimes a specific process at a production site can become a bottleneck for the entire supply chain. With an appropriate planning tool, you can model production processes at site level, for example, to identify the cause of capacity bottlenecks in manufacturing:

– Specific throughput of the production line

– Degree of utilisation of production resources, shift models

– Warehouse capacities

For a deeper insight into planning manufacturing capacity, you can watch the following how-to video. The video shows you how to set up what-if scenarios with anyLogistix to evaluate the performance of a supply chain in terms of meeting daily production schedules.

Quelle: The AnyLogic Company