Our series: Supply Chain Simulation / Part 3

What is a supply chain simulation?

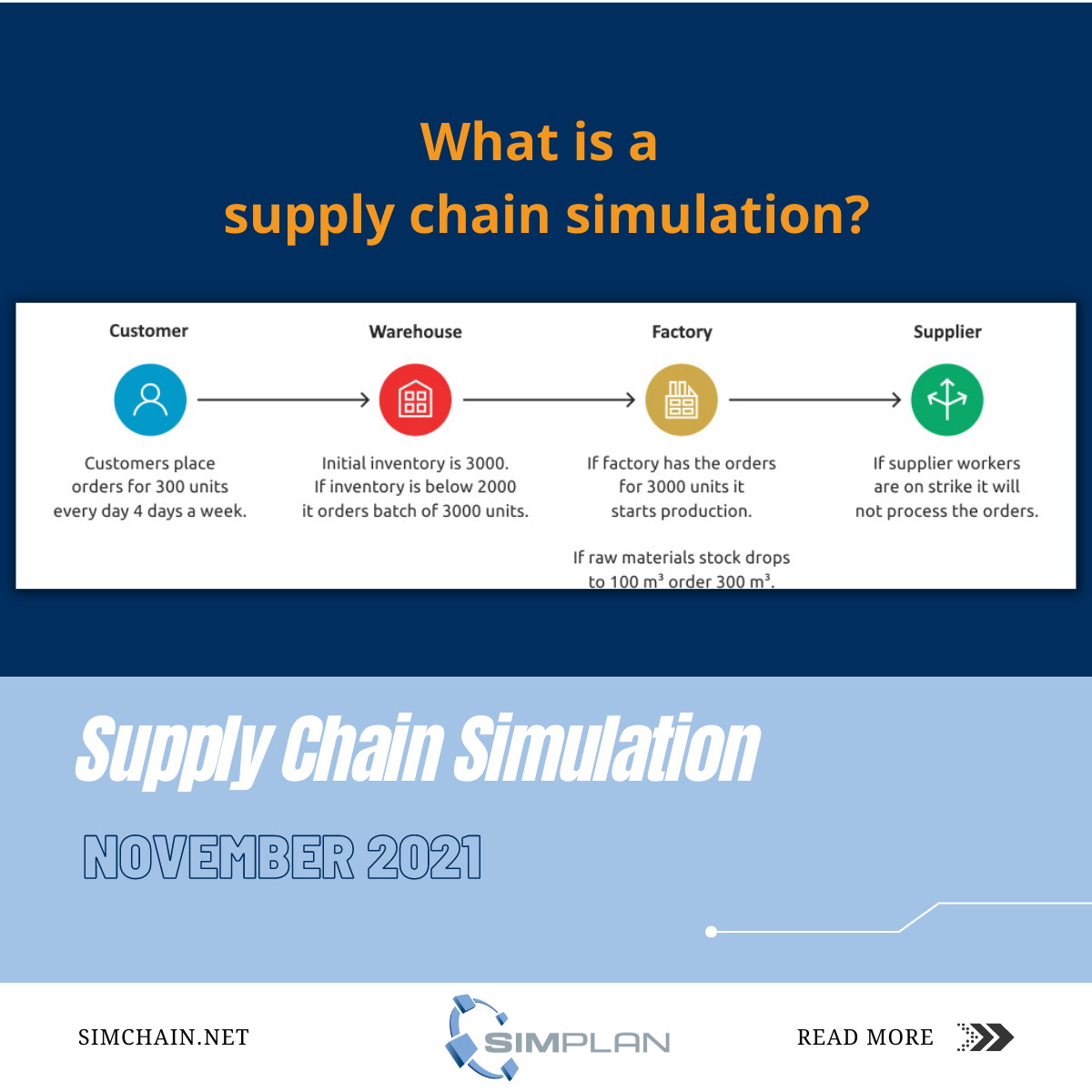

A supply chain simulation shows the behavior of a logistics network over time. The logical rules of a supply chain are modeled in a simulation model and then executed at runtime. For example, production of a SKU is started when orders reduce inventory below a certain threshold. Such rules can be combined and their relationships to each other examined, as well as tested for disruptive events such as strikes and natural disasters.

Supply chain simulation models differ from analytical models (greenfield analysis and network optimization) in several important ways.

An analytical model of a supply chain uses linear equations to describe the operations. This has the advantage that once solutions are found, they are optimal. However, this is also a disadvantage: describing a supply chain in this way requires simplification. Consequently, the difficulty of modeling increases with complexity. It should also be noted that analytical models are of limited use outside their scope.

Simulation models of a supply chain capture all relevant processes, allowing you to consider all dimensions of your supply chain. The results of a simulation model show system behavior over time, and any descriptive statistics about how your supply chain is functioning can be captured. Simulation models for supply chains are also suitable for mapping complex processes and can account for stochastic events.

With the two different approaches, professionals are faced with the decision of which method to use in which case. In our next article, we will go into this in more detail.

Would you like to learn more? Make an individual appointment for a web seminar with our supply chain expert Till Fechteler or send an email to info@simplan.de.