Our series: Supply Chain Simulation / Part 9

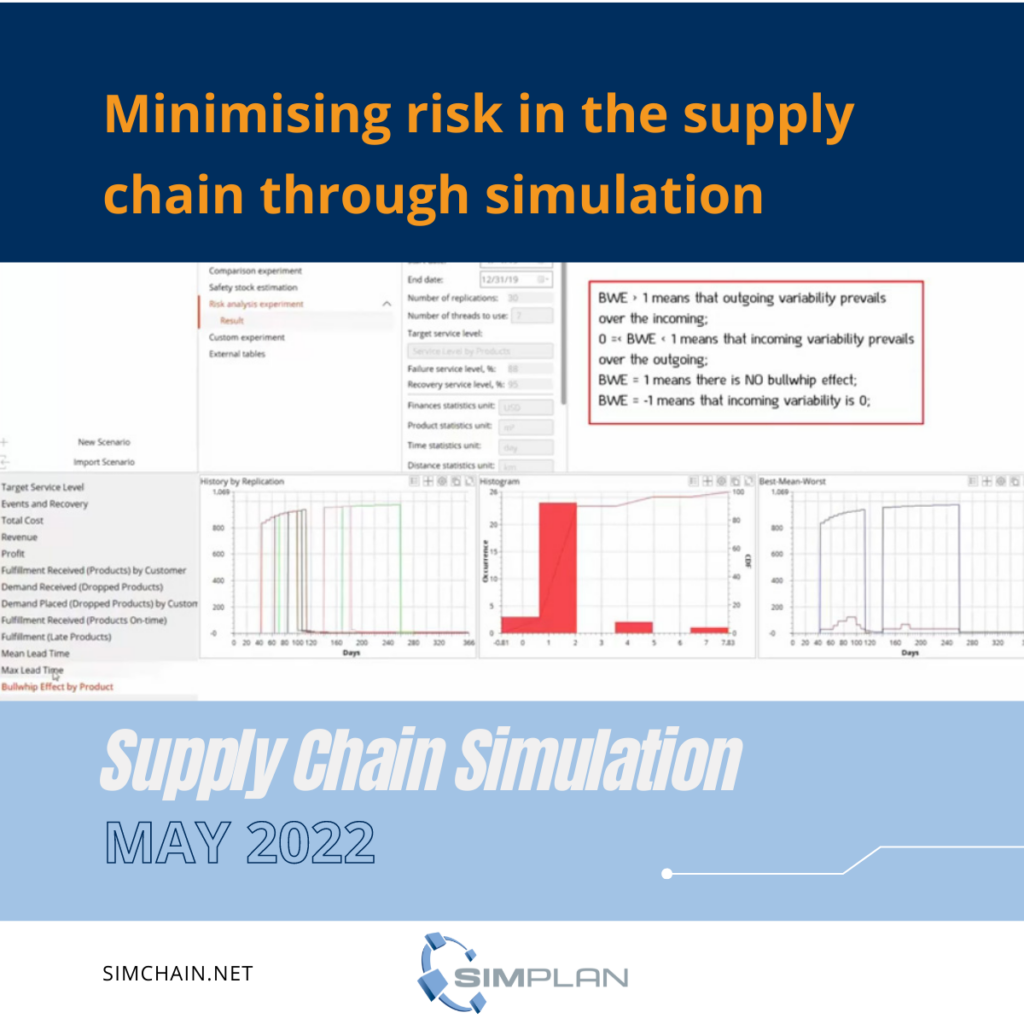

Minimizing risk in the supply chain through simulation

Supply chain operations are exposed to many risks. Research shows that supply chain managers spend 40-60% of their working time managing disruptions. It doesn’t have to be that way. Better understanding, planning and management can minimize risk costs and maximize business objectives.

The replication of the supply network with the help of software allows weighing the risks

Software, such as anyLogistix (ALX), allows users to replicate a supply network and simulate its operations in great detail. In doing so, the imponderables of the real world can be taken into account. This cannot be done with traditional analytical supply chain risk management tools. In addition, simulation allows users to test multiple scenarios for network or policy changes to increase supply chain resilience and define contingency plans.

The creation of a digital twin enables quick decisions in critical situations

Data reflecting the status of a supply chain can be fed into a simulation model to create a digital twin of the supply chain. This enables fast and informed decision making when it is needed most – as a critical situation develops. With ALX, supply chain risk mitigation is achieved not only through planning, but also through an effective response that is backed by simulation.

The software enables effective risk management

It is important that the software is able to handle both operational and disruptive risks. This is critical to the effectiveness of supply chain risk management.

Operational risks can be:

- Bullwhip-effect (uncertainty of supply and demand)

- Demand fluctuations, including those caused by forecast errors and bullwhip effect

- Risks in connection with delay in transport, damage to or loss of goods, rejects

- Supply bottlenecks at the company’s own plants or at suppliers due to inappropriate warehousing strategies

- Equipment failures in production

- Modification of customs duties, taxes, industrial or environmental regulations

Disruptive risks include:

- Bankruptcy of suppliers or logistics providers

- Damage to transport or production infrastructure due to natural or man-made disasters

- Economic and political crises

Source: The AnyLogic Company