Our series: Supply Chain Simulation / Part 4

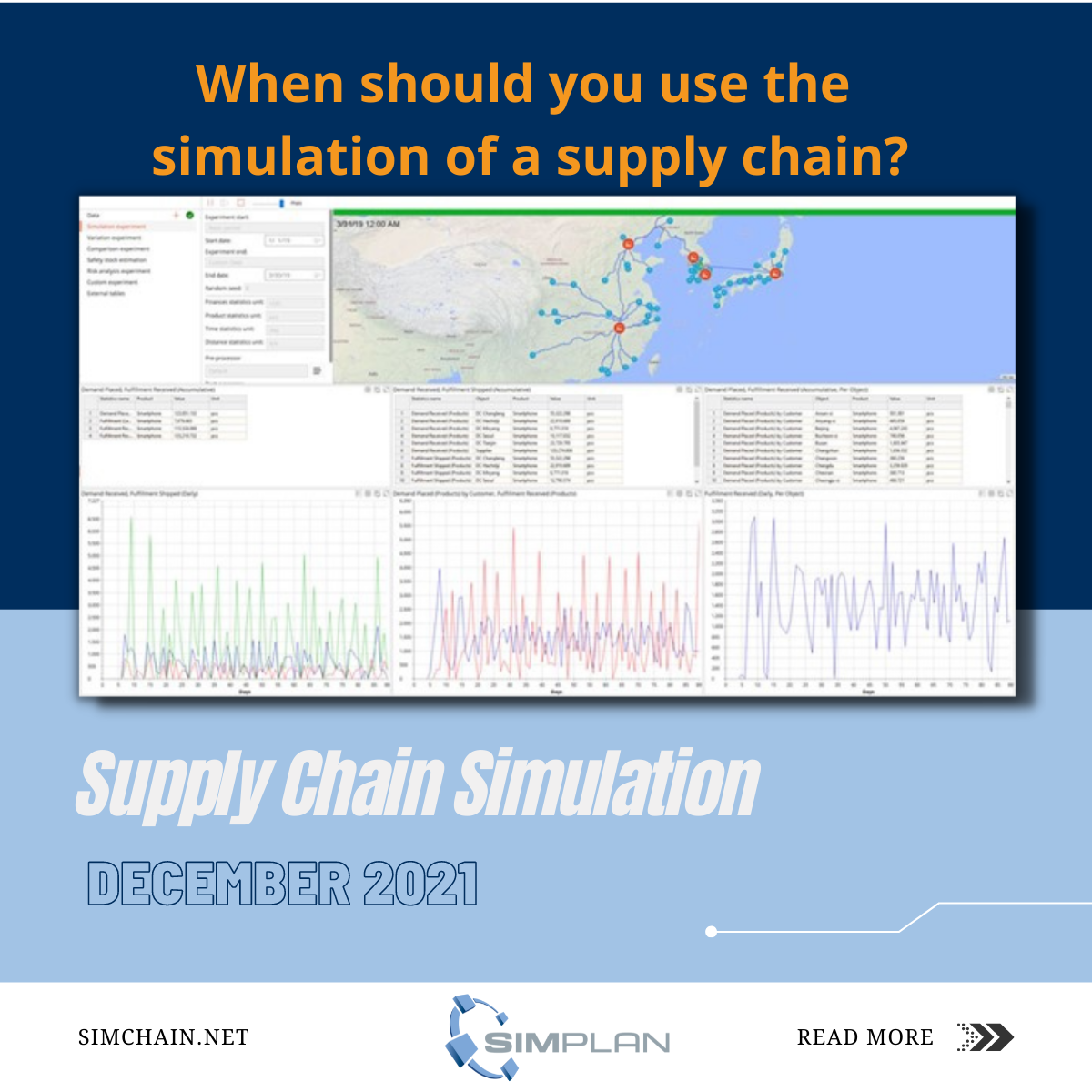

When should you use supply chain simulation?

In our last article, we highlighted the technical differences between dynamic simulation of a supply chain and analytical methods. Today, we take a closer look at the application areas of the methods.

Analytical methods (greenfield analysis and network optimization) are mainly used to solve location decision problems, e.g. where should a central warehouse for a new sales region be located or is a centralized or decentralized supply network structure more cost-effective.

If you want to know something about the processes in your network or if you need key figures over time (e.g. delivery service level, utilization of transports or SKU stocks), then you need a simulation model of the supply chain. In addition, modern supply chains generate a lot of data and are exposed to a variety of risks. These two factors increase the complexity of the analysis, favoring simulation modeling over analytical methods.

Simulation can be used as follows:

- Determining safety stock levels in supply chains across multiple stages.

- Evaluation of inventory management strategies

- Identification of bottlenecks

- Cost of maintaining a specified delivery service level

- Test the robustness of your supply chain

- Ask what-if questions, e.g., regarding new production facilities or transportation strategies

Analytical optimization and dynamic simulation together form a powerful combination of methods. They complement each other perfectly in solving supply chain design problems and form the basis for developing an advanced supply chain. With anyLogistix, you can fully model your supply chain and reap the benefits of both methods together.

Contact us and let’s optimize your supply chain together! Want to learn more? Make an individual appointment for a web seminar with our supply chain expert Till Fechteler.